Templot Club Archive 2007-2020

|

|||

| author | remove search highlighting | ||

|---|---|---|---|

|

posted: 9 Aug 2015 05:18 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Greetings fellow Templotters, As some of you already know, I've been messing about trying to print turnout bases on a 3D printer. It's fairly easy to create a 3D model of the timbers in CAD from any Templot template. It's also fairly simple to drag models of the chairs into the correct positions and orientation and combine them to produce an STL file to drive a printer. What is not so easy is producing 3D models for chairs that a) actually work, and b) don't look too horrible! I think I have reached a point where I'm limited by the printing technology itself. The results are actually a lot better than I thought they might be when I started out. Anyway, I've been making some wild guesses about chair dimensions, and I have not had a lot of luck finding anything on the Web. Any information would be greatly appreciated. (Here's a bit of track I've been using to test the latest chair design.)undefined Cheers!Andy |

||

| Attachment: attach_2150_2734_DSCN1813.JPG 2548 | |||

|

posted: 9 Aug 2015 06:11 from: Martin Wynne

click the date to link to this post click member name to view archived images |

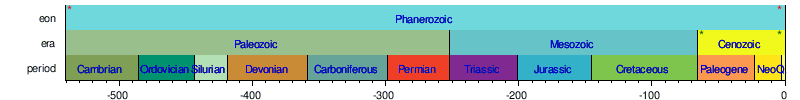

Hi Andy, Chairs vary quite a bit across different periods and companies. There are drawings of "Standard Railway Equipment" (i.e. REA) chairs here. These would be your best bet for the majority of bullhead models: http://www.scalefour.org/downloads/gwrtracknotes/R4290A.pdf Plus several pages of specifically GWR chairs here (drawings 1734 - on): http://www.scalefour.org/resources/gwrtracknotes regards, Martin. |

||

|

posted: 9 Aug 2015 08:00 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Hi Martin, Thank you very much! From a 3D printer perspective, the bigger the better. Based on your information it looks as if I'm not too far off. BTW, in case you had not already guessed, my ulterior motive for posting here was the possibility that someone might take this to the next level. It's beyond my capability, but I'm pretty sure someone "skilled in the art" could cook up a program that automatically combines models derived from Templot with models of the appropriate chairs to produce a stereo lithography file that can be fed to a 3D printer. Cheers!Andy |

||

|

posted: 10 Aug 2015 07:59 from: Les G click the date to link to this post click member name to view archived images |

My local Maker-Space has a number of 3d printers; I have been custodian-between-meetings for one of them for about 18months. During that time we have encountered a number of limitations of printer capability. The relevant issue with printing sleeper and chair as a component, is that the home DIY printers deposit plastic onto a plate, on ours it is heated glass. This deposition process means that any overhangs are unsupported. Test prints of arch-like components all show a degradation of the under-surface at the top of the arch, amounting to about 30 degrees of arc. It follows that the part of the chair which grips the rail will always be imprecise. Great care would be needed to obtain accurate gauging, and there would also be mechanical difficulties when fitting the rails to the chairs in a complex formation There are layer deposition processes in which the layers are formed by fusing powdered plastic which supports overhanging shapes, but the machines are very expensive. None of this takes anything away from the potential of linking Templot output to drawing software for the purpose of producing STL files for bespoke timbers for use in conventional hand-built track, then using moulded chairs eg C&L or Exactoscale. Les G |

||

|

posted: 10 Aug 2015 10:17 from: Paul Boyd

click the date to link to this post click member name to view archived images |

At work, we use a company called Shapeways for prototyping. There are various material options, some of which are eminently suitable for track work. Costs are reasonable as well - this company makes it feasible for hobbyists to upload and print using a professional SLS process. Put it this way, using Shapeways made far more sense for us than buying a "home" 3D printer with all its limitations. I suppose I should say that I have no connection with the company! |

||

|

posted: 10 Aug 2015 10:31 from: Howard

click the date to link to this post click member name to view archived images |

Les G wrote: ...the home DIY printers deposit plastic onto a plate, on ours it is heated glass. This deposition process means that any overhangs are unsupported. Test prints of arch-like components all show a degradation of the under-surface at the top of the arch, amounting to about 30 degrees of arc.For filament deposition printers (such as the Makerbot I use for the MERG kits) the effect of temperature can help overcome this. The two servo mount kits illustrated were printed at different temperatures. The higher temperature makes the filament (PLA in my case) less viscous and so it does not span the gap. 1547_100524_220000000.jpg  undefined undefinedBTW it would help if the scale/gauge were mentioned in these posts. I'm assuming O gauge, but I could be wrong. Howard Watkins. |

||

|

posted: 10 Aug 2015 10:34 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Paul, David Rayner uses the Shapeways service for his "Off The Rails" track parts in 7mm scale, see: http://www.shapeways.com/shops/otr topic 1503 - message 9375 regards, Martin. |

||

|

posted: 10 Aug 2015 10:54 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Howard wrote:BTW it would help if the scale/gauge were mentioned in these posts. I'm assuming O gauge, but I could be wrong.Hi Howard, Andy's experiments are in 4mm scale. He has a long topic about it on RMweb: http://www.rmweb.co.uk/community/index.php?/topic/100879-printing-turnouts-on-a-3-d-printer/ By the way, your attached image is an empty file. Did you exceed the 6MB limit? It's better to use the Image Gallery for pictures: http://85a.co.uk/forum/gallery_view.php?display=ALL#gallery_top edit: I see you did upload it to the Gallery. I have edited your message to include it. regards, Martin. |

||

|

posted: 10 Aug 2015 16:20 from: Les G click the date to link to this post click member name to view archived images |

Howard wrote: For filament deposition printers (such as the Makerbot I use for the MERG kits) the effect of temperature can help overcome this. The two servo mount kits illustrated were printed at different temperatures. The higher temperature makes the filament (PLA in my case) less viscous and so it does not span the gap. Howard, What you describe matches our droopy experience of overhangs with a RepRap, and with a Mendel90. It is not too serious a problem generally, one can make an allowance in the model to allow a sufficient degree of manual fettling; or design the component to avoid it. Model railway Scale is not relevant to the work we have been doing, but when I model it is usually in 4mm. As a matter of interest, what temperature do you use for your extrusion of PLA ? Les G |

||

|

posted: 10 Aug 2015 19:13 from: Trevor Walling

click the date to link to this post click member name to view archived images |

Les G wrote: Hello, For some reason I always thought higher temperatures meant greater viscosity and more likelihood of unsupported overhangs drooping. Regards. Trevor. |

||

|

posted: 11 Aug 2015 11:10 from: Les G click the date to link to this post click member name to view archived images |

You are correct: Lower viscosity = stiffer; higher viscosity = more free flowing. Higher temperature makes the plastic more liquid, and more likely to droop. This is why temperature and filament feed speed are controlled. Hence my query about extruder temperature for successful bridging. Les G |

||

| Last edited on 11 Aug 2015 11:18 by Les G |

|||

|

posted: 12 Aug 2015 01:32 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Ah yes! This sample is OO gauge - I should have mentioned that. Thanks Martin. I'm using the cheapest printer I could find a couple of years ago, a Printrbot Simple. The unsupported overhang issue does not present a problem for me, and I'm able to get very consistent dimension and gauge results. At the moment I'm working on optimizing the chair designs for turnouts and finding the method that allows me to generate a turnout with the least effort. I'll post the results when I have something I'm satisfied with. BTW, I'm printing with PLA through a 0.25 mm nozzle. PLA is interesting stuff. Although it has a rather low melting point, it's quite hard, and it makes turnout bases that are surprisingly rigid, sufficiently so that it's possible to drag straight rail through the chairs for wings and checkrails. More to follow (PS - My Templot message alerts are no longer going to spam.) |

||

| Last edited on 12 Aug 2015 01:43 by Andrew Barrowman |

|||

|

posted: 12 Aug 2015 10:26 from: LSWRArt

click the date to link to this post click member name to view archived images |

There are some nice 3D printed 7mm chairs here - unfortunately not available in 4mm. http://www.shapeways.com/shops/otr I have used some of these check rail chairs for point construction. The only problem is that, for super fine detail, the plastic is quite hard and therefore rather brittle. You have to be quite careful pushing the chairs onto the rail - especially as you are trying to move along two rails as once, but they are certainly nicely detailed and look the part. Certainly at this scale and with these hard plastics there is no problem with droop. Regards, Arthur |

||

|

posted: 12 Aug 2015 12:40 from: Howard

click the date to link to this post click member name to view archived images |

Les G wrote: You are correct: Lower viscosity = stiffer; higher viscosity = more free flowing.The left hand image was done at 200 degrees, the right hand one (with drooping filament) at 220 degrees. Too low a temperature can mean parts do not adhere to the bed plate. Howard. |

||

|

posted: 12 Aug 2015 12:44 from: Howard

click the date to link to this post click member name to view archived images |

Martin Wynne wrote:I see you did upload it to the Gallery. I have edited your message to include it.Thanks Martin, I don't know why the picture was not included even though it was in the Gallery. I must be doing something wrong. Howard. |

||

|

posted: 12 Aug 2015 21:58 from: Les G click the date to link to this post click member name to view archived images |

Howard wrote: The left hand image was done at 200 degrees, the right hand one (with drooping filament) at 220 degrees. Too low a temperature can mean parts do not adhere to the bed plate. Thank you Howard, We are currently printing PLA at 210 initial then 200 for the main print. Our Mendel90 has a nozzle at 0.4 mm. We are using a glass plate heated to 60 degrees. Adhesion is rarely a problem as long as the glass is squeaky clean; we use paper towel and meths for cleaning between prints. There have been adhesion problems with small diameter prints at around 6 mill diameter or less; a cure for this was to place the small cylinder on a sacrificial larger thin disc base and truncated cone. Another problem was found when printing a cylinder with 2mm dia spigot; the plastic became distorted due to insufficient cooling time between layers. This was completely resolved by printing six components at a time. It took about seven seconds to complete each layer in the set, by which time the previous layer had cooled sufficiently to be stable. regards Les G |

||

| Last edited on 12 Aug 2015 21:59 by Les G |

|||

|

posted: 13 Aug 2015 09:51 from: Howard

click the date to link to this post click member name to view archived images |

Les G wrote: The printer used by MERG is a Makerbot Replicator2. This also has a 0.4mm nozzle but no heated bed plate. For a large box (17cm x 8cm) I had problems with a corner lifting during printing. I tried helper discs http://www.makerbot.com/blog/2013/04/19/keep-corners-flat-with-makerwares-helper-discs but this did not solve the problem. I am now printing on BuildTak and that works http://shop.3dfilaprint.com/buildtak-3d-printing-platform-surface-1200-p.asp For very small objects I have also used double sided adhesive tape on top of the normal blue painter's tape. Howard. |

||

|

posted: 13 Aug 2015 14:00 from: Les G click the date to link to this post click member name to view archived images |

I have read about the problems of adhesion on unheated plates. There appears to be a high level of frustration from those who describe the need for cleaning off adhesive prior to fitting new tape. Contrast that with a 30 second wipe and polish with a bit of paper towel and a dab of methylated spirit. In my view, the heated plate solution is the logical way to go. It also provides a very smooth base surface which can be used to advantage. Les G |

||

| Last edited on 13 Aug 2015 14:01 by Les G |

|||

|

posted: 13 Aug 2015 17:28 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

I'm using blue masking tape on an unheated metal bed. Seems to work well enough for me. I always give the tape a light rub with sandpaper between prints to remove any residue from the PLA and to provide a bit of key on the surface. The Z-axis zero position is critical. My printer is a bit flimsy, so I have to keep a close eye on the Z adjustment to ensure a good first layer. I've also found it's better to use a honeycomb fill on the bottom layer rather than make it solid. |

||

|

posted: 2 Jan 2016 03:52 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Turnout stereo lithography file. | ||

| Attachment: attach_2194_2734_Doh6p5v5R.stl 384 | |||

|

posted: 2 Jan 2016 03:56 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Andrew Barrowman wrote: Turnout stereo lithography file.Hi Andy, Thanks for the file. I have downloaded it. Now what? Do you have a link for the software to use it? regards, Martin. |

||

|

posted: 2 Jan 2016 10:27 from: Howard

click the date to link to this post click member name to view archived images |

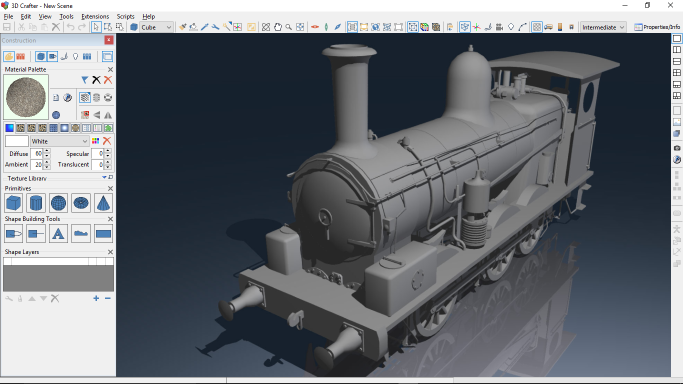

Martin Wynne wrote: Andrew Barrowman wrote:You can use the free download of the Makerbot Desktop to view the fileTurnout stereo lithography file.Hi Andy, http://www.makerbot.com/desktop I had to rescale the turnout to fit, undefined At 0.1mm resolution it would take 1.5 hours to print; I might give it a go later. 1547_020513_550000000.png  Howard Watkins |

||

|

posted: 2 Jan 2016 18:23 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Howard wrote: Martin Wynne wrote:Mind how you go with that Howard. It may not be what you expect. We parked it there so that Martin could take a look at it with Meshlab.Andrew Barrowman wrote:You can use the free download of the Makerbot Desktop to view the filehttp://www.makerbot.com/desktopTurnout stereo lithography file.Hi Andy, Before you try to print it, you might want to run it through Netfabb to repair any defects. The .stl was produced in TurboCADpro16, and it sometimes has issues. Also, you might want to add webs to connect the timbers. I left them out for viewing clarity. I have attached the .box file that generated the design. You can find photos of similar turnouts I produced on RMweb. My "handle" there is AndyID. I'll post some of the shots on this thread in a bit. |

||

| Attachment: attach_2195_2734_Doh6p5v1.box 359 | |||

|

posted: 2 Jan 2016 19:04 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Andy, MeshLab keeps crashing on my system. For simply viewing and rotating the image, the free eDrawings viewer from Solidworks seems to be working much better. Download from: http://www.edrawingsviewer.com 2_021402_240000000.png  regards, Martin. |

||

|

posted: 2 Jan 2016 20:07 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Howard wrote: Martin Wynne wrote:Andrew Barrowman wrote:You can use the free download of the Makerbot Desktop to view the fileTurnout stereo lithography file.Hi Andy, Hi Howard, I just realized that you might be going to print the rails too. They are only there for cosmetic effect. They are not designed for printing. The rail web is very thin, and you would probably need to add supports of some sort to prevent sagging. I have printed check rails in the past, but not using that design. regards,Andy |

||

|

posted: 2 Jan 2016 21:04 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Andy, RMweb has gone down, so here is the .box file I just posted on there. This is for the 4ft-1.5in gauge templates which I have been playing with. I'm not sure what you are waiting for? regards, Martin. |

||

| Attachment: attach_2196_2734_4ft_1p5in_gauge_templates_00_bf.box 309 | |||

|

posted: 2 Jan 2016 21:10 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Yes, I think I broke it when I replied Thanks Martin. That's exactly what I need. I'll add the 3D elements to it so we can view it. |

||

|

posted: 3 Jan 2016 04:29 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

undefined I uploaded them to the Gallery but I can't seem to figure out how to Insert them into the message. (Using Chrome on Windows10.) edit: Now resolved Using FireFox 2983_022322_090000004.jpg  2983_022322_080000000.jpg  2983_022322_080000001.jpg  2983_022322_080000002.jpg  2983_022322_090000003.jpg  |

||

| Last edited on 4 Jan 2016 07:35 by Andrew Barrowman |

|||

|

posted: 3 Jan 2016 07:24 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

.stl file of a 00-BF V-6 turnout attached. This file is intended for viewing only. It requires further editing before 3D printing. |

||

| Attachment: attach_2198_2734_MW1b.stl 289 | |||

|

posted: 3 Jan 2016 10:17 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Andrew Barrowman wrote: I uploaded them to the Gallery but I can't seem to figure out how to Insert them into the message.Hi Andy, Google Chrome is the new Internet Explorer, doing its own thing with web sites. Generally Firefox is the best option for this site (and many others). This is how to insert images using Google Chrome (and Safari): 1. don't use the long Gallery buttons on the posting editor. Instead use the blue Gallery Upload button at the very top of the page. It will open in a new tab, so that you don't lose your post. 2. upload your image(s) to the Gallery. 3. display the required image in the Gallery. 4. right-click on it, and select Copy Image Location or Copy Image Address to get the image URL. 5. back on the posting page, click this button: image.gif  6. paste in the copied URL and click OK. 7. the image will be inserted in your post. It may be immediately visible, or you may need to click Preview to see it (depending on how your browser is feeling today). After previewing you can scroll back down to continue posting. This web site uses some rather old code. It's been rock-solid reliable for years, but unfortunately browsers keep changing and it needs updating to something more modern. When I can find the time. regards, Martin. |

||

|

posted: 3 Jan 2016 11:46 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Andrew Barrowman wrote: .stl file of a 00-BF V-6 turnout attached.Hi Andy, Looking very good. Thanks for doing this. 2_030641_500000000.png  Note that the crossing chairs (A, B, C, X, Y) need to be skewed so that they are square to the centre-line of the vee. Also chair "A" should be a slab & bracket design, with a through bolt (for a 1950s design). We will let you off that (for now). The old style of cast "A" chair is ok for earlier periods. regards, Martin. |

||

|

posted: 3 Jan 2016 12:17 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Andy, I have increased the upload limit to 10MB in case you need to upload larger STL files. Attachments on this forum are stored as a BLOB in the database (Binary Large Object) which is not ideal but it seems to be working fine in practice. Fortunately the donations fund is happily covering the web costs at present. regards, Martin. |

||

|

posted: 3 Jan 2016 13:03 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Andy, This is Templot's native DXF export (3D setting), viewed in eDrawings: (This is the 1:7.5 crossing.) 2_030750_010000000.png  It doesn't seem to be possible to import a DXF into MeshLab? It's now about 15 years since I wrote the DXF export function in Templot, and things have obviously moved on. How would I go about implementing an export for 3-D printing files? There seems to be a bewildering array of file formats to choose from, and a lack of good documentation about their internal structure (unless I'm missing the obvious -- I found this: http://mech.fsv.cvut.cz/~dr/papers/Lisbon04/node2.html ). regards, Martin. |

||

|

posted: 3 Jan 2016 18:29 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Thanks for all the help Martin. I shall attend to those errant chairs shortly I'll post a couple of screen shots from TurboCAD later to shed some light on the assembly process. I'm lazy, so I had to make it as easy as possible. From what I can see the STL file format seems to be emerging as the common interchange standard for 3-D printing, but it's all quite new to me so I could be entirely wrong. Cheers, Andy |

||

|

posted: 4 Jan 2016 03:42 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Andrew Barrowman wrote: .stl file of a 00-BF V-6 turnout attached.New and improved! |

||

| Attachment: attach_2199_2734_MW1e.stl 308 | |||

|

posted: 4 Jan 2016 03:44 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Andrew Barrowman wrote: Andrew Barrowman wrote:I took the liberty of equalizing the timbers on this version..stl file of a 00-BF V-6 turnout attached.New and improved! |

||

| Attachment: attach_2200_2734_MW1g.stl 308 | |||

|

posted: 4 Jan 2016 06:47 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Some screenshots of the assembly process using TurboCAD. The outline template is imported into TurboCAD as a DXF file from Templot. Only the gauge edge of the rail is used. It's best not to include the other edge in the DXF. The timber outlines and centerlines are used. The Blocks panel to the right of the first shot contains models for the various chairs required. They all have a reference point that lies on the plane corresponding with the bottom surface of the timbers. The template is placed on that plane. The various blocks are simply dragged from the Blocks panel and their reference (yellow dot) is snapped on to the template at the intersection of the rail gauge edge and the timber centerline. TurboCAD has a rubber stamp feature that lets you stamp the same block repeatedly with one mouse click. I've used it here to replicate a number of three bolt chairs on the template. 2983_040211_290000000.png  Some of the chairs will need to be rotated after stamping them in place. 2983_040211_300000001.png  Here one chair has been selected and has been rotated and realigned with the direction of the rail by dragging the X handle and snapping it on to the rail edge. 2983_040211_310000002.png  The timbers are extruded to the desired height with two mouse clicks. I have extruded one in this shot but I find it best to position all the chairs before extruding the timbers. 2983_040211_310000003.png  To avoid having to make lots of different chairs for all the possible crossing angles I make the chairs at the Vee from a few sub-components. Slightly more complicated, but not much. Other than adding webs to interconnect the timbers, that's about all there is too it. I do not "add" the chairs to the timbers to make a single solid object. There is no need to do that, and if I did, it would make it much more difficult to revise a turnout design. Using blocks allows me to modify a block design and immediately apply it to every instance of that block in the turnout. |

||

| Last edited on 4 Jan 2016 07:30 by Andrew Barrowman |

|||

|

posted: 4 Jan 2016 13:12 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Andy, Many thanks for that. It seems that adding and aligning the chairs is a tedious process? One which Templot might possibly be able to do itself? Then you could create one-off 3D files to print any template in a full track plan, rather than a few fixed turnout sizes. It would likely need a "shove chairs" function similar to shoving timbers to resolve any conflicts, such as replacing an ordinary chair with a bridge chair where needed. Which means the chairs would also need to be visible on the trackpad. So the first question is -- are your chairs in a format which will import into Templot using the existing DXF import function (in the background shapes)? Is it possible you could send me, or attach here, a DXF file containing just one of your chairs? I can then experiment with getting Templot to include it in the DXF export. Preferably the file would be in the DXF text format, rather than binary, so that I can read it. I can probably convert it if not. What I'm still very hazy about is how we get from a drawing in TurboCAD to something a 3D printer can use? I've been reading that the STL format is many years old, dating from before 3D printers became generally available, and is generally regarded as too low in resolution for them? Does your printer lay the filaments in horizontal sections, i.e. everything at one Z dimension in one go, and then step up to the next section and repeat? Or does the head move in 3 dimensions simultaneously, laying down flat angled faces for example? I spent years programming for that sort of thing in CNC milling using ball cutters and special-profiled D-cutters, but I'm thinking 3D printing is not quite the same. For example is a round filament the only option? I can see that in some applications a nozzle which extruded a flat strip might be more useful, especially if could by done at an angle from a swivellable nozzle, adding a K dimension to the X,Y,Z. I can see that I am going to have to get one of these 3D printers and experiment before I can make sensible changes in Templot. I have found this before, no amount of asking folks or reading docs gets me enough information. For example making Templot dpi-aware for hi-res tablet computers. The only way I could do that was to get one and try it. It was a lot of work, and expensive, but I'm very pleased with the result. But there has been minimal feedback on the subject. I wonder how many Templot users do have 3D printers or intend getting one? regards, Martin. |

||

|

posted: 4 Jan 2016 19:18 from: Trevor Walling

click the date to link to this post click member name to view archived images |

Hello, This stuff is really interesting and impressive. Using Templot for 3D printing would take it to a whole new level. I I wonder how many Templot users do have 3D printers or intend getting one?I have a printer from "RepRapPro". A Mendel from about two or three years ago.It has been superseded by more capable and easier to build models.Information about most aspects is available on their web site. The speed of change and progress in this field is breathtaking. There are sites where you can download files of objects to print "Thingiverse" being one. I haven't got round to learning a CAD program to design something for printing myself yet, but it is on my ToDo list. Regards. |

||

|

posted: 4 Jan 2016 20:06 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Martin Wynne wrote:This is for the 4ft-1.5in gauge templates which I have been playing with.Here are the same templates converted to 4ft-0.5/8in gauge in 4-SF (16.2mm gauge). There is no suggestion that 4-SF is suitable for commercial RTR pointwork, so I have changed the length of these to match the vee-rail joints in the usual way (CTRL-6 and CTRL-8 peg positions). The plain track is set to 27 8ft sleepers per 60ft rail, with similar spacings in the turnouts. The idea is to create prototype 4ft-0.5/8in track to carry the same weight of traffic as 4ft-8.1/2in gauge track. Martin. |

||

| Attachment: attach_2201_2734_4ft_0p6in_gauge_templates_4_sf.box 334 | |||

|

posted: 4 Jan 2016 20:33 from: Nigel Brown click the date to link to this post click member name to view archived images |

Martin Wynne wrote: I wonder how many Templot users do have 3D printers or intend getting one?Hi Martin I'm interested in 3D printing, mainly because it looks to be a means of creating bits and pieces in 3mm/ft which aren't there at the moment. The idea of taking say a drawing of a dome or chimney and being able to convert it into something printable is enormously attractive, particularly for the more uncommon prototypes I'm thinking of. However, I'd almost certainly use Shapeways (or other similar services), partly because I think they can afford a much higher quality printer than I could, and it would save me a lot of time, and probably money, going in that directive. Today's home printer could be junk tomorrow. I'll stick to working out the software Cheers Nigel |

||

|

posted: 5 Jan 2016 00:23 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Martin Wynne wrote: Hi Andy,Hi Martin, Three bolt attached. It's the only format that TurboCAD allows me to save it in. Probably binary, but I don't really know. The reference point should lie at the intersection of the two lines floating beneath the solid body. That should put the bottom surface of the rail 1.8 mm above the bottom surface of the 1.2 mm thick timbers on my prints. BTW, this chair works with SMP Code 75 BH rail, but it might need to be adjusted for BH rail from other suppliers. It's not too terribly tedious to position the chairs on the template, but it would be interesting to see if it could be automated. It might depend on whether or not you want to completely eliminate the CAD step. If a CAD step was retained, one way to accelerate the process would be to put dummy "blocks" in the 3D DXF from Templot. There would be different dummies for the various chair types. They would only need to be positioned and oriented correctly. TurboCAD lets you select a block in a model then replace it and all the other blocks of the same name with a different block. With that method it would not take long to populate a template with the desired set of chairs and it would be independent of gauge, scale, clearances etc. If the CAD step was to be eliminated, I think Templot would need to include a similar feature that allowed the user to include a library of chairs that Templot selected from and positioned in the 3D model. I don't think a "universal" set of chairs will work too well. For example, if you were building 7mm turnouts (which I think is a really great application for 3D printing) you would probably want to include a lot more refinement than it is possible to include at 4mm scale; to some extent the chairs have to be designed to reflect the limitations of the printing process and print medium at the desired scale. There are a few more steps involved to print a CAD model. I'll list them the way I happen to do it: 1. Create the 3D model in native TurboCAD format. 2. Save the TurboCAD model as a STL file. (It's really a bunch of models in their desired relative overlapping positions.) 3. Import the STL file into Netfabb Basic - it repairs any holes and other issues and creates a single surface model in another STL file. 4. Import the repaired STL file from Netfabb into a slicer program, in my case SLIC3R. This takes the STL file of the model and slices into layers which are exported as a G-code file to drive the 3D printer. Yes, the printer prints a single horizontal layer (slice) at one Z axis height before moving on to the next layer. The layers are usually all the same thickness, but they do not have to be. It is possible to generate custom G-code that does it differently, but I suspect that would be a major undertaking. The big issue with additive printing is ensuring that a layer fuses properly with the previous layer. That's difficult enough in a single plane. Doing it in 3D motion is probably not impossible, but I suspect it would take a lot of experimentation to get satisfactory results. I probably only answered half your questions, so keep asking! Best, Andy |

||

| Attachment: attach_2202_2734_Chair1.dxf 431 | |||

|

posted: 5 Jan 2016 07:34 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Andrew Barrowman wrote:I probably only answered half your questions, so keep asking!Hi Andy, Thanks for the file. It is indeed in the text version of DXF so I can read it, thanks for that. (If you change the file extension to .txt you can read it in Windows Notepad or wherever.) Unfortunately I haven't been able to extract anything meaningful from it. I tried opening it in half a dozen programs, and the only one which would even look at it was, er, Templot. I used the DXF import in the background shapes (you saved it in INCH units), and got this: 2_050214_470000000.png  but no sign of a chair. It also included a cross-hairs target mark at (67000, 21486) mm which as you can imagine caused some indigestion. But even after removing that, the file still won't display anything in any other software. Which is puzzling because they ought to display at least the above, if Templot can. It does include a chunk of unreadable code at one place in the file, which means nothing to me. I know I am a long way from being up to date in CAD software, but even the latest eDrawings2016 displays only a few single dots. Is there any way you can save it in a format I can use? For example after selecting DXF file type in the TurboCAD save dialog, can you click the Setup button and make these settings: 2_050214_480000001.png  Reading your description of the post-processing which these files need before they become usable on the 3D printer, it seems this whole process is still a long way from being very user friendly? regards, Martin. |

||

|

posted: 5 Jan 2016 08:15 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Attached version might be better. I removed the junk that was in a 2-D page tab and set the origin to something more sensible. This is what I see when I use setup (I didn't even know it was there!) Does any of it look helpful? It does not mean much to me. 2983_050309_580000000.png  Yes, the process isn't exactly "shake and bake", but the additional steps are quite mechanical and require little concentration. ab |

||

|

posted: 5 Jan 2016 08:32 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Ah! I can see it using eDrawings viewer. It's in the bottom right-hand corner. There are some dots in the file that need to be eliminated. | ||

|

posted: 5 Jan 2016 11:06 from: Charles Orr

click the date to link to this post click member name to view archived images |

Hi Martin, I have a Rep Rap Pro Omerod which I built from a kit. It took some time to set up but generally produces acceptable prints. I am going to get a Maker Bot Replicator 2 very soon. This the one that MERG uses to produce some of its kits. Best regards Charles |

||

|

posted: 5 Jan 2016 11:20 from: johnbirch72

click the date to link to this post click member name to view archived images |

Nigel I would certainly stick with outside printers for 3D work now. I use Chris Ward (http://www.cwrailways.com) who produces good results and tends to be cheaper than Shapeways with faster turnround which removes a lot of frustration. John |

||

|

posted: 5 Jan 2016 12:28 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Andrew Barrowman wrote: Attached version might be better. I removed the junk that was in a 2-D page tab and set the origin to something more sensible.Hi Andy, Attached version? Did you forget to attach it? In the setup, please can you try ticking these options: 2_050642_530000000.png  It may announce that what you have can't be saved in that format, but it's worth a try. I'm intending to get a more up-to-date CAD package so that I can make sense of all the 3D printer stuff which is now available. I do have DesignSparkMechanical, which is free software from RS Components (a big electronics distributor in the UK) intended for rapid prototyping for 3D printing. It can open and create STL files -- this is your STL file: 2_050703_120000000.png  http://www.rs-online.com/designspark/electronics/eng/page/mechanical Be warned, the download is a massive file -- 467 MB. It declares itself "unlicensed" to open DXF files, but it is willing to save to DXF. So I can possibly extract the chairs from the above and get them into DXF. Thanks again, I will do a bit more experimenting. regards, Martin. |

||

|

posted: 5 Jan 2016 16:34 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Well I thought I had attached it |

||

| Attachment: attach_2204_2734_Chair2.dxf 388 | |||

|

posted: 5 Jan 2016 17:11 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Andrew Barrowman wrote: Well I thought I had attached itHi Andy, That's great, many thanks: 2_051203_480000000.png  Hopefully I can get Templot to insert it in the DXF output where required. It contains this chunk of code which means nothing to me, but hopefully if inserted "as-is" it will work. Any idea where I should be looking to discover how to decode this? 2_051206_300000000.png  Now to conduct some experiments -- I may be some time... edit: well this is a start: http://help.autodesk.com/view/ACD/2016/ENU/?guid=GUID-19AB1C40-0BE0-4F32-BCAB-04B37044A0D3 regards, Martin. |

||

|

posted: 5 Jan 2016 17:19 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Hi Martin, First screen grab is chair2.dxf viewed in eDrawings. The chair is in the bottom right hand corner. I think the five dots in the upper left hand corner could be elements of a 3-D axes indicator. I can reload the dxf file into Turbocad without a problem. The dots are not graphic elements in the file. The second grab is the zoomed in view of the chair. I tried saving a version with the settings you suggested, but the chair is not visible when I view it in eDrawings. I've attached that version (chair3.dxf) to this message. ab 2983_051205_200000000.png  2983_051205_580000000.jpg 2983_051205_580000000.jpg |

||

| Attachment: attach_2205_2734_Chair3.dxf 359 | |||

|

posted: 5 Jan 2016 17:22 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Snap! No clue at all about the junk I'm afraid. I've never even looked in any of the files. |

||

|

posted: 5 Jan 2016 17:28 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Andrew Barrowman wrote: No clue at all about the junk I'm afraid. I've never even looked in any of the files.I don't think it is junk, I think it is your 3D data. Many thanks for the second file. Now I can diff the two and discover how to set the DXF version number in the exported file, to match the above "junk". At first sight the two files are very similar. Thanks again, Martin. |

||

|

posted: 6 Jan 2016 00:14 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Andy, First signs that this might work. 2_051906_110000000.png  Templot wouldn't import your DXF file. But it would after I opened it in my old copy of TurboCAD and saved it again. The first task would seem to be to get some radiused corners on these 2D chairs. There is already a dialog for some chair data -- it has been in Templot for about 15 years and never yet used, see real > chairs / baseplates > chair / baseplate data... Click the ? info buttons for some notes about each dimension. regards, Martin. |

||

|

posted: 6 Jan 2016 01:20 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Hi Martin, For the sake of drawn appearance you might radius the corners, but for printing at this scale it's a waste of time, it's only going to make the stl file even bigger, and that slows down the pre-printing process, a lot. (I know this first-hand.) The printer automatically puts a radius on the corners. I'm interested to see if you can insert a "blocks" into the template. I'll send you a file that includes a few examples in a bit. Best, ab |

||

|

posted: 6 Jan 2016 20:41 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Andrew Barrowman wrote:For the sake of drawn appearance you might radius the corners, but for printing at this scale it's a waste of time, it's only going to make the stl file even bigger, and that slows down the pre-printing process, a lot. (I know this first-hand.)Hi Andy, I was thinking that the presence of the sharp corners in 2D might be a factor when shoving chairs to avoid conflicts, for example: 2_061531_270000000.png  (That is from Len Newman's P4 templates, which are available as downloads to Scalefour Society members. I'm currently working to get these usable in the background shapes as metafiles.) I'm thinking that we are going to need 2 linked chair objects. One in 2D to see and shove on the trackpad and use in 2D DXF exports, and one suitable for 3D printing to include in 3D exports (DXF or STL). regards, Martin. |

||

|

posted: 6 Jan 2016 22:20 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Hi Martin, I see what you mean. I actually allow the 3-D chair models to overlap slightly if they are too close "I'm thinking that we are going to need 2 linked chair objects. One in 2D to see and shove on the trackpad and use in 2D DXF exports, and one suitable for 3D printing to include in 3D exports (DXF or STL)." Yes, I think you are correct. I'm a bit concerned that, if Templot produces an STL file for the printer, Templot is now to a great extent responsible for the results. I would suggest you don't provide that option until you have tried a bit of printing yourself. Initially I'd suggest DXF output only. That's why I'm interested to see if Templot can output chairs as correctly positioned and oriented blocks. That allows a user to easily substitute their own chairs in CAD. The Templot "chair" could be a simple box shape. The blocks might only need to be two dimensional representations in the template. I'm trying to see if that's possible, but so far I don't have conclusive results. Best, ab |

||

|

posted: 6 Jan 2016 22:29 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

I should have said "see if I can export and import blocks in DXF format" I'm trying to get TurboCAD to do it, but no luck so far. | ||

|

posted: 6 Jan 2016 23:18 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Andy, I feel that I'm sinking in a sea of file formats. This is your DXF file. At present Templot can't import anything from this: 2_061809_060000000.png  This is the result of opening it in TurboCAD and saving it in R12 version of DXF: 2_061811_080000000.png  Templot happily imports this using my original 15-year-old code. Also, the file doesn't contain anything which I can't read. From TurboCAD I can export this in 3DS format, which looks identical, and there are some online tools for converting 3DS to STL. However, when I tried them the results look nothing like a chair. I'm not planning to create STL files in Templot. But what I would like to find is a simple path from the DXF files which Templot can export, to STL files (or some other format related to 3D printing). As I recall you are doing that via TurboCAD? However my old copy of TurboCAD won't save in STL format. regards, Martin. |

||

|

posted: 7 Jan 2016 03:17 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Hi Martin, Here is a very basic DXF file. It seems to be compatible with TurbocadPro16 and TurbocadDeluxe21 both for reading and writing. The file consists of two "blocks", a 2D rectangle block and a 2D triangle block. If it's possible to insert some copies of these into a DXF template at various locations and with various alignments, and they survive as identifiable blocks when I import the DXF into Turbocad, I should be able to immediately substitute 3D chair blocks at the same locations and with the same alignments. If that does not work, we might be up a gum tree Cheers, ab |

||

| Attachment: attach_2206_2734_DXFtest1.dxf 319 | |||

|

posted: 7 Jan 2016 08:49 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Andrew Barrowman wrote: Here is a very basic DXF file. It seems to be compatible with TurbocadPro16 and TurbocadDeluxe21 both for reading and writing. The file consists of two "blocks", a 2D rectangle block and a 2D triangle block.Hi Andy, I'm not clear what you want me to do with this file? It won't display in my old copy of TurboCAD, nor import into Templot. However, I managed to get it into Templot by: 1. opening it in ProgeCAD Smart 2. saving in DXF R14 format 3. opening that in TurboCAD 4. saving in DXF R12 format with exploded blocks 5. importing into Templot: 2_070347_090000000.png  What now? This is what I'm seeing in Edrawings, and also in ProgeCAD Smart: 2_070315_310000000.png  2_070316_310000000.png  2_070327_300000000.png  regards, Martin. |

||

|

posted: 7 Jan 2016 09:18 from: Martin Wynne

click the date to link to this post click member name to view archived images |

p.s. I can also get it into Templot by exporting from ProgeCAD as an EMF metafile, and importing that into Templot as a picture shape: 2_070414_100000000.png  From which I can probably extract the metafile records, which could then be included in the DXF export. (This is what I'm currently experimenting with for the P4 templates which I mentioned earlier.) Martin. |

||

|

posted: 7 Jan 2016 17:38 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Hi Martin, Sorry it's getting so complicated. I found some info on blocks here http://www.autodesk.com/techpubs/autocad/acadr14/dxf/blocks_in_dxf_files_al_u05_c.htm I can see these block structures in the last file I posted, so that is at least something. What I hope we might be able to do is get Templot to produce a DXF file that has simple two-dimensional "blocks" positioned on the template at the places where chairs should be located. Each type of chair (3 bolt, bridge, check, etc, etc) would be represented by a unique two-dimensional block in the DXF exported by Templot. (If I understand correctly, they don't even need to be different shapes. Each type just needs to have a unique block name.) The rectangle and triangle blocks I included in the test file are just examples of two-dimensional blocks that we might use for testing purposes. There is no reason to use them if you can produce blocks in the template by another method. If you can create a DXF in Templot with the 2-D blocks at the correct locations on the timbers it is very simple to substitute the actual 3-D chairs in TurboCAD for the 2-D blocks in the DXF imported from Templot. In Turbocad I can replace all the blocks with a particular name with blocks of another name with a couple of keystrokes. Hope this makes a bit more sense Andy |

||

|

posted: 7 Jan 2016 18:13 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Andrew Barrowman wrote: What I hope we might be able to do is get Templot to produce a DXF file that has simple two-dimensional "blocks" positioned on the template at the places where chairs should be located. Each type of chair (3 bolt, bridge, check, etc, etc) would be represented by a unique two-dimensional block in the DXF exported by Templot.Hi Andy, That's exactly what I have been working on today. I have concluded that these "block markers" can't be easily included in the background shapes or loaded via the DXF import. They need to be something separate, generated by Templot itself, and included in the DXF export. This requires a new layer in the DXF export, so will need some work on the DXF export code (which I haven't looked at for years). I have dusted off (literally) my 1985 AutoCAD User Handbook and been re-reading the chapter on generating DXF files. If I don't need to include in the export any previously-imported complex 3D data, the whole process moves up several notches on the doable scale. So I hope to have something you can try fairly soon. regards, Martin. |

||

|

posted: 7 Jan 2016 18:55 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Great! Thanks. | ||

|

posted: 7 Jan 2016 20:43 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Hi Martin As I mentioned, I have TC16Pro and TCdeluxe21. They don't have compatible native file formats, but they can exchange files in DXF format. I have attached the DFX for the latest version of the RMweb rendering without the rails but including webs to attach the timbers. I think I still need to adjust a couple of chairs for 1.3 mm check rail clearance, but it should be OK otherwise. TCdeluxe21 is available in the US for $70 from CAD and Graphics at the moment (there is also later version available for a bit more). This file should be editable in TCdeluxe21, and it TCdeluxe21 can output STL files. There seem to be a large number of duplicated blocks with auto-generated name associated with this file, but the ones I produced seem to be there too. There is also an free evaluation version of TCdeluxe available, but it may have restrictions. Hope this is helpful. Andy |

||

| Attachment: attach_2207_2734_MW1gP1.dxf 318 | |||

|

posted: 7 Jan 2016 22:49 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Mind how yo go with that file. It has some issues when open it in TCdl21 | ||

|

posted: 9 Jan 2016 04:26 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Attached is a partial turnout with some blocks representing different chair types. It's in Turbocad Deluxe native file format (produced on version 21). Please change the file extension back to .TCW before attempting to use it. (I changed the extension to .ANY to upload it.) As it's a slightly tedious process to convert the chairs from Turbocad Pro into this format I have only converted a few of them so far. Please let me know if you are using Turbocad Deluxe and I'll convert the rest. Andy |

||

| Attachment: attach_2209_2734_ChairsJan8TC21.any 254 | |||

|

posted: 9 Jan 2016 06:53 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Andy, You have lost me again. Currently I am working in Templot to create "chair markers" represented by primitive rectangle outlines on Templot's own output. In the DXF file they are exported as inserted blocks, which can be replaced with proper chairs by editing the file in a CAD program. The blocks will be named to match the prototype REA chairs, "S1", "L1", "M1", "P", "1.P", "2.P", "CC", etc., to allow editing with replacement blocks. As such, I don't need you to send me anything. With the best will in the world, I can't sensibly attempt to write my own export function to output a modern 3D-modelling CAD format, it would take up all my time for months. I have been looking at OpenSCAD: http://www.openscad.org and I may be able to get Templot to export a suitable script, and/or include a copy of OpenSCAD within Templot itself to create such files. My TurboCAD is version 8 from 2001, it won't open this latest file. Does it contain anything I need? I do have a later version of ProgeCAD, which works with AutoCAD DXF and DWG files up to 2007, but won't open TCW. regards, Martin. |

||

|

posted: 9 Jan 2016 17:25 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Hi Martin Sorry for the obfuscation You can safely ignore that file. I posted it in case you or anyone who is following along wanted to try the block manipulation/substitution method using TurboCADdeluxe. If you download the evaluation version of TC you could use it to test block substitution from a DXF produced by Templot, but that is not essential at all. Cheers, Andy |

||

|

posted: 10 Jan 2016 14:14 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Andy, I'm very impressed with the way you have converted Templot's native 3D export with hollow rails: 2_030750_010000000.png  to a full bullhead section: 2_021402_240000000.png  Is there anything Templot can do to assist that? Also, obviously for 3D printing it needs some webs between the timbers. That could be implemented in the DXF quite easily by exporting the rails additionally as a thin layer at the base level of the timbers. Is that how you are doing it? regards, Martin. |

||

|

posted: 10 Jan 2016 20:23 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Hi Martin, Actually, I don't use the 3D DXF export. I only use the 2D export. I used the "sweep" function in TurboCAD (only available in the expensive Pro version unfortunately) to create the rails. The function works by sweeping a profile along a line, or in this case, a polyline. I reference the rail profile to the gauge edge of the rail in the 2D export from Templot, invoke the function, and presto-chango! One thing that would help would be if the gauge lines were represented as continuous polylines in the DXF. At the moment they are a series of discrete lines which I have to join into a polyline before I can run the sweep. That's the only thing I can think of. You may have noticed I make no attempt to plane the switch rails. I just let them merge with the stock(?) rails. If we wanted to get fancy I suppose we could swing one of the points and plane the rail by taking a slice off it in Turbocad. At the crossing Vee I just merge the two rails then slice off the overhangs. You can see how the web under the nose is missing leaving the nose unsupported! (I also knocked a piece off the Vee to blunt it a bit If you wanted to go to the trouble, the unsupported nose could be fixed by providing sweep lines on the template that replicate the bends you use to make Vees using your bend, solder and file method. To add the webs for printable turnouts, I deleted the rails (obviously) and added webs using the same method that I used to create the rails, only this time sweeping the profile of the web along the gauge polylines. IIRC, I had to slice off some extraneous bits under the wing rails. Everyone is likely to have their own ideas about how wide and thick webs should be, and even where to position them. For example, I could print them as very thin layers that filled the entire space between the rails (almost like a sheet of paper) then just put the ballast on top, so I'm not sure you should go to the trouble of adding 3D webs or even 2D webs, but if you do, try to make them single entities so they are easy to delete or reposition in CAD. To some extent the same thing applies to the timbers. I don't remember what the issue was, but I ran into problems trying to use the 3D timbers from Templot. Again, everyone is likely to have different ideas about how deep they should be. I know the "real" depth in Templot could be set to produce the desired dimension, but it takes me a bit of mental gymnastics to get there, and I'd still have to measure the depth in CAD to make sure I didn't muck it up. If the timbers in the 2D exported Templot DXF are closed polylines, it's really very simple to extrude them to the desired height in Turbocad. It only takes one click on each timber. It might be even simpler in other CAD software. Even if the timbers are not closed polylines, it takes very little effort to overlay them with a "rotated box" by snapping on three of the corners. Hope some of this makes sense. Best regards, Andy |

||

|

posted: 10 Jan 2016 21:28 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Andy, Thanks for the detailed reply. I'm a bit concerned at the amount of work needed on Templot's DXF export before it can be used for 3D printing. Obviously for commercial printing of fixed turnout sizes, that doesn't matter too much, you have to create the printer file only one time. But most users of Templot create a track plan in which all the templates are different, each to be 3D printed only once. I'm also hoping that whatever post-processing of the DXF is needed can be done by users in free software. We won't be much further forward for most users if it needs an expensive CAD package. How long does it take you to convert a Templot DXF file into a file usable on the 3D printer? At present not all the lines in the file are exported contiguously, so creating polylines from them could be tricky. For example both ends of a timber are exported before the sides. But creating polylines from the rail edges should be doable. You can see the order of exported entities by importing Templot's DXF export back into the background shapes. If you click in the shapes list, you can run up and down the list by holding down the up-down arrow keys on the keyboard, and watch each entity being highlighted in red: 2_101618_410000000.png  which may help you to see what's happening in the file. regards, Martin. |

||

|

posted: 10 Jan 2016 22:39 from: madscientist click the date to link to this post click member name to view archived images |

Currently I am working in Templot to create "chair markers" represented by primitive rectangle outlines on Templot's own output. That would be a neat feature of it was on the template output. , it would add chair placement for modern functional chair based turnout construction. Dave |

||

|

posted: 10 Jan 2016 22:51 from: Martin Wynne

click the date to link to this post click member name to view archived images |

madscientist wrote:That would be a neat feature of it was on the template output, it would add chair placement for modern functional chair based turnout construction.Hi Dave, Yes, it's intended that they should be on the printed template. The problem of course is they get covered over when the timbers are fixed over them. Which means printing a duplicate template as a reference. In which case you may just as easily refer to the excellent Exactoscale templates, which are far more detailed. It will be possible to change the dimensions of the chair markers to represent different prototypes, but only as simple rectangles at this stage. regards, Martin. |

||

|

posted: 10 Jan 2016 23:28 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Ah! Thanks Martin. I'll take a look at that. I've never timed myself adding the 3D elements to the template, and, as it's still a bit of a "work in progress" I usually find myself tweaking the process or elements as I go along. I estimate it should take about 30 minutes. Of that, the biggest chunk is snapping and aligning the chairs on the template. The next biggest time consumer is probably getting the chairs around the "frog"" sorted. I don't have models for all the possible crossing angles, so I make the chairs out of several components. That time could be eliminated if I took the time to create a comprehensive library of chairs for the common crossing angles. If you can get the chair markers to work that would make a huge difference. You could stop there for now. All the stuff about creating polylines might be nice to have, but it's non-essential. There are plenty of other very fast CAD methods that can be used to add the webs, and it's unlikely that sweep will ever be available in a low-end or free CAD product, so I would not worry about sweep lines for now. Same applies to the timbers. I think the current 2D versions are just fine. One small thing - I don't want the non-gauge side of the rail on the template. It's a nuisance when I am trying to snap the chairs to the correct intersection. I eventually figured out how to get only the things I want in the DXF, but it took me quite a while, and I've probably forgotten how I did it by now. If there was some sort of canned profile for the DFX it would help. Maybe there already is and I just don't know how to do it I'm not sure about freeware CAD programs. I've tried a few and I thought they were all horrible. Whatever CAD is used, it will have to support Blocks. If there is a freeware version that does that it might be OK for populating the template and generating the .STL I'll poke around a bit and see what I can find. Some of the free versions are really evaluation versions that put limits on the number of elements in a model. That would be a big problem here. TurboCAD deluxe isn't free, but it's not terribly expensive at $70, but it could be a bit off-putting for many people. Please holler if I have not made myself clear. I blame the Scottish/American accent. Best, Andy PS - If I had the frog chairs all sorted out and you can get the block markers into the DXF, I think the CAD time would only be around ten minutes. |

||

|

posted: 11 Jan 2016 01:01 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Andrew Barrowman wrote:One small thing - I don't want the non-gauge side of the rail on the template. It's a nuisance when I am trying to snap the chairs to the correct intersection. I eventually figured out how to get only the things I want in the DXF, but it took me quite a while, and I've probably forgotten how I did it by now.Hi Andy, program > generator > generator settings > rails > rail head gauge-faces only menu option. Then program > generator > rebuild all background menu item. Same process to remove the outline extension marks on the timbers. If there was some sort of canned profile for the DFX it would help. Maybe there already is and I just don't know how to do itYes, your generator settings can be included in your program preferences, and you can create several different preferences files, with or without these or other settings, as you wish: program > main program panel, then preferences > begin saving preferences... menu items. But please read the notes. n.b. warning to beginners -- don't include the generator settings in your program preferences until you know what you are doing. regards, Martin. |

||

|

posted: 11 Jan 2016 01:42 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Many thanks Martin. That will help a lot. | ||

|

posted: 18 Jan 2016 00:49 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Andy, I thought you might like an update on this. I have got the bare bones working, but there is still a lot to do before we have a usable new function with the multitude of different prototype chair sizes. It needs a new data structure just to contain them all. Plus new "shove chairs" functions to make them adjustable on each timber. This below is with equalized timbers. 2_171925_020000000.png  Which means it will be possible only to include a basic experimental output in the next program update, otherwise it will be delayed for months. I know for DXF substitution you need only the block markers, but the chair outlines are needed so that you can see what you are doing. And everyone else can see them. regards, Martin. |

||

|

posted: 18 Jan 2016 02:54 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Hi Martin, Thank you for the update. Please don't hold up the next release for this If you can include the single block marker that is oriented correctly at each rail gauge-line/timber center-line intersection, that will still be a huge step forward. What I would do with it then is to import a 2D Templot dxf into cad and substitute three bolt chairs for all those markers. From there it is really simple to highlight, for example, all the chairs that should be check-rail chairs and substitute those for the three bolt chairs, etc., etc. If you have a sandbox version that I can somehow access, I'll be happy to test it for compatibility with cad applications. Thanks and regards, Andy |

||

|

posted: 18 Jan 2016 07:42 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Andrew Barrowman wrote:If you can include the single block marker that is oriented correctly at each rail gauge-line/timber center-line intersection, that will still be a huge step forward.Hi Andy, Yes, I know, it sounds simple when put like that. The fly in the ointment is that that isn't always the correct place for the chair. Because the chair outlines are not symmetrical about the gauge-face, putting a skewed chair on the intersection doesn't centralize the chair within the width of the timber. And different chairs have different amounts of non-symmetry. A "P" slide-chair is close to being symmetrical, but a "L1" bridge chair is a long way off. With square-on timbering only half the chairs are skewed, but some of them significantly. With equalized timbering, the skewing is less but some skewing applies to nearly all of the chairs. To illustrate that, here I have intentionally exaggerated the lack of symmetry. You can see that the gauge-face intersection with the centre-line of the chair does not coincide with the centre-line of the timber: 2_180233_350000000.png  I know it is only a small difference, but the human brain being what is, even a small offset from being central within the timber width is very noticeable. And in most prototype cases, wrong. However, as you can see, I think I have got it working. regards, Martin. |

||

|

posted: 20 Jan 2016 23:42 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Hi Andy, Another progress report. 2_201814_250000000.png  2_201814_490000000.png  A few notes about this. Initially this is going to be restricted to the REA bullhead designs for switches A to D, with hard-wired chairing data. Partly because I have the full chair designs for those, but mainly because a complete customized chairing implementation is going to be a massive task and other things are more important first. I still have a lot to do -- the L1 bridge chairs, check rail chairs, crossing chairs. The P slide chairs are always aligned to the stock rail, As you can see, chairs remain aligned to the rails when the along and twist functions are applied to the timbers, or both applied together. The crab function won't be supported at this stage, the chairs don't move if a timber is crabbed sideways. Nor obviously if a timber is thrown, or the length or width of the timber changed. Also at this stage, the return curve part of a parallel-type V-crossing will not be chaired. But it's looking hopeful. The plain rectangular chairs don't look very impressive alongside the detailed PDF templates from Exactoscale. But of course in Templot the templates are fully adjustable for crossing angle, curvable to any radius, and can be swapped between square-on and equalized timbering styles as required. regards, Martin. |

||

|

posted: 21 Jan 2016 00:51 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Hi Martin, "Oh what a tangled web...." etc. Do not be fooled by any sense that I might be able to detect the difference between a 1PL and a 1PR, or any other chair for that matter. Wot I do is "plonk 'em down" where they seem to fit Perhaps, more importantly, I'm just a wee bit alarmed that so few (possibly not any) modellers have jumped on the 3D bandwagon. I think I offered to make my models available to anyone who wants to give it a shot, but so far the reaction has been, to put it mildly, just a bit underwhelming - OK, it was non-existent. I'm not entirely sure what to make of this. There is no end of weeping, a not unexpected amount of wailing, and a commensurate amount of gnashing of teeth (not to mention rending of garments) on a site that we know regarding the cost/difficulty of making decent looking turnouts for a reasonable price. The best thing of all is that 3D printing lets a modeller use any old scale/gauge/standard they care to choose (just like Templot). A cynic might suggest that some are looking for an excuse rather than a solution Anyway, if you don't mind plodding on, so will I, just as long as we realize that we might be shoving the proverbial boiled egg up a gum tree, while maintaining a sense of humor (always a good thing I think). Cheers! Andy |

||

|

posted: 21 Jan 2016 01:42 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Andrew Barrowman wrote:I'm not entirely sure what to make of this. There is no end of weeping, a not unexpected amount of wailing, and a commensurate amount of gnashing of teeth (not to mention rending of garments) on a site that we know regarding the cost/difficulty of making decent looking turnouts for a reasonable price.Hi Andy, What puzzled me -- well no actually it didn't -- is that so many of those asking for more prototypical track then complained when actual details of prototype track were posted. For the first few years of Templot's life there were very few users modelling in 00 gauge. That's how 00-SF went unnoticed in the gauge list for so many years. http://www.scalefour.org/forum/viewtopic.php?f=39&t=4629 I think if we can get to a situation where users can create a track plan in Templot, and then get the whole thing 3D printed with full chairing (one section at a time, of course), there is going to be a lot of interest from track builders. With full chairs there is the problem of threading the bent rails, but I'm still hopeful of finding a solution where those rails can be dropped in prototypically. Followed by inserting a miniature key on a break-off slug, or maybe by heat-sealing the open jaw down over the rail with a suitable shaped bit on the soldering iron. As soon as I have got a DXF out of this, and you have proved block substitution in CAD and successful printing, I'm going to be getting one of these printers myself and experimenting. At present the chairs are a bit primitive compared with the injection-moulded ones created by Len Newman, but everything has to start somewhere. I can still remember gluing unidentifiable bits of white metal over rivets. regards, Martin. |

||

|

posted: 21 Jan 2016 03:24 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Hi Martin, 3D printed chairs that use an additive process are never going to be quite as good as injection-moulded chairs, but I defy anyone to tell the difference from a distance of a couple of feet. Also, if the printing process is set up properly a turnout can be assembled without any gauges and adjustments. I understand you are building in 7mm. That should be an even better application of 3D printing. Let me know before you spring for a printer. I might have some suggestions, and I can definitely help you get your printer set up properly. It's not rocket science, but there are some interesting details. But be warned - watching it print you next turnout can become slightly addictive. Cheers! Andy |

||

|

posted: 21 Jan 2016 05:31 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Martin Wynne wrote:whereas the 1PL, 1PR, etc., block chairs are always square-on to the main road.Well that has always been my understanding, and all the switch drawings I have show this. Including the Exactoscale templates. Unfortunately it cannot be. There is only one pair of L and R block chairs in each size, which are used for both left-hand and right-hand switches. The chair drawings clearly show the outer jaw for the stock rail square to the rail, with the inner jaw angled to match the switch rail (blade): 2_210026_220000000.png  I have therefore now modified the code for this: 2_210052_560000000.png  Unless and until anyone can shed more light on this? regards, Martin. |

||

|

posted: 21 Jan 2016 18:20 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Hi Martin, Can you point me at a list of the various chair types? The information I have is all from the 1930's. Regards, Andy |

||

|

posted: 21 Jan 2016 18:41 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Andrew Barrowman wrote:Can you point me at a list of the various chair types? The information I have is all from the 1930's.Hi Andy, See: http://www.scalefour.org/downloads/gwrtracknotes/R4290A.pdf That is Paddington's 1959 re-drawing of the Standard Railway Equipment (REA) chair designs and contains a few differences in the dimensioning compared with the original SRC designs. Not enough to make a a difference in a model. The GWR and BR(W) always had to be different. AS1 is an ordinary chair. AS1J is a joint chair used on 12" wide sleepers adjacent to rail joints. I can't find an online source of the original 1923 designs. They are in the NERA reprint book of the LNER 1926 SRC Permanent Way drawings. regards, Martin. |

||

|

posted: 22 Jan 2016 04:45 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Martin Wynne wrote: Andrew Barrowman wrote:Thanks for that Martin.Can you point me at a list of the various chair types? The information I have is all from the 1930's.Hi Andy, Do you have access to the Permanent Way Institute's Handbook? It seems to have some relevant information, but I've only skimmed over it. Regards, Andy |

||

|

posted: 22 Jan 2016 04:51 from: Martin Wynne

click the date to link to this post click member name to view archived images |

Andrew Barrowman wrote:Do you have access to the Permanent Way Institute's Handbook? It seems to have some relevant information, but I've only skimmed over it.Hi Andy, Yes, a couple of editions. What information do you want? regards, Martin. |

||

|

posted: 22 Jan 2016 05:28 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

Sorry for the confusion (again) Martin I thought you might find it helpful if you didn't already have it. |

||

|

posted: 22 Jan 2016 21:32 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |

For anyone who interested in dabbling in 3D, TurboCAD deluxe V20 is on sale at the moment from Cad and Graphics in the US for $49.99 (35 GBP?) Obviously a bit more expensive than any of the free CAD programs out there, but it does work very well, and I'll be happy to help anyone who wants to give it a shot. (I'm not connected in any way with either of these companies.) |

||

|

posted: 22 Jan 2016 23:03 from: Nigel Brown click the date to link to this post click member name to view archived images |

Andrew Barrowman wrote: For anyone who interested in dabbling in 3D, TurboCAD deluxe V20 is on sale at the moment from Cad and Graphics in the US for $49.99 (35 GBP?)Hi Andrew TurboCAD deluxe V20 is currently on offer from Amazon UK at £9.75. Looks a good buy. I have TurboCAD designer V20 which is 2D only, like it. I use it for drawing up artwork for etching. I find TurboCAD thinks the way I think, more than some other alternatives I've looked at. Cheers Nigel |

||

|

posted: 22 Jan 2016 23:18 from: Andrew Barrowman

click the date to link to this post click member name to view archived images |